- Home

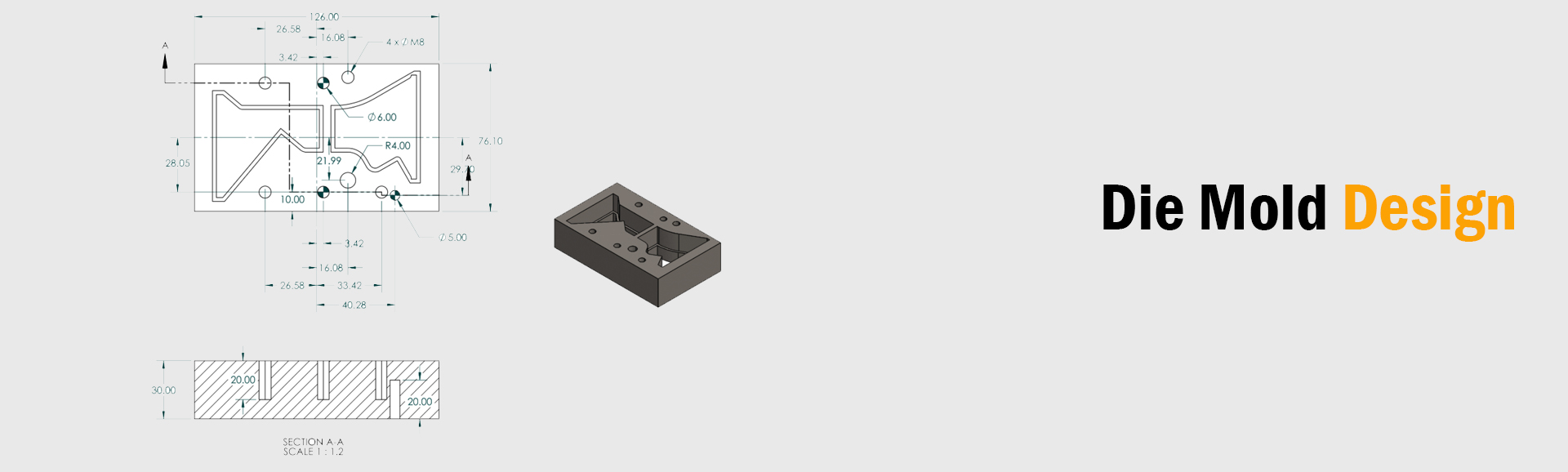

- Rubber Moulding Die Design

REQUEST A QUOTE

Why Choose Experienced Manufacturers For rubber moulding die design

With many companies offering runner molding services, it has become challenging for you to pick the best company. We have always claimed to be the most reliable assistants for the rubber moulding die design . However, you must know why we can meet your requirements better than the rest of the competitors. Hear us out, and then make your decision.

Experience matters in die mold design

We are glad to let you know that we have been serving this industry for a considerable time. In these years, we have handled countless assignments and have been able to satisfy the customers with the final look and functions of the products.

- Experience is essential to suggest and apply netter techniques during the process to make the perfect mould.

- Experience is also important to enhance the skillset of the tea who will execute the moulding process. During molding die design , the injection into the rubber or plastic mould should be such that there is no vacuum or air gap inside the cavity.

We have been dominating the industry over the past few years and will continue to do so with the confidence of our team of experts.

Perfection in information collection about die mold design

Before starting the job, we are particular about collecting and sorting relevant part designs, equipment, and process details. Also, a hearty interaction with the client is necessary to ascertain whether the mould and die design is vital for the perfect execution of the process.

- We have learned from our experience that we need to know the details about the final product to assess the feasibility of applying the molding die technique.

- The material that will maintain the shape of the mould must be strong enough to provide support even when we inject the metal or alloy under pressure.

In every aspect, you will notice that the need for expert designers who have sufficient knowledge and practical experience will be ideal for the job.

Structural analysis before die mold design

Now, this is again crucial for the manufacturing of the end product. We can understand what you want from the procedure. And we will explain what you can expect and what not to expect from the design process.

- We maintain a check on all the parameters related to the dimensions of the product.

- The weight of the product is a crucial factor, and we might have to change the die mold design depending on the requirements of clients.

When you approach an amateur company with the demands, you may get a non-satisfactory response. But expert, experienced people like us possess the maturity necessary to handle such projects. Hence, we focus on all the vital aspects of the task and manage the projects accordingly.

Best cold forging die design from 3d Cad Design Service

The most advanced cold forging die designs are available on 3D CAD design service, which incorporates cutting-edge technology and industry knowledge. Our team of skilled designers creates high-quality die designs that are tailored to your specific requirements with a thorough understanding of the cold forging process and a dedication to precision engineering.

Process of making cold forging die design

We use cutting-edge CAD software and the power of three-dimensional modeling to create intricate die designs that are meticulously detailed. Our planners cautiously investigate the attributes of the material being fashioned, taking into account factors like its solidarity, pliability, and stream conduct. Because of this, we are able to improve the cold forging die design of the die to get the best efficiency and quality out of the product.

Durability and long-lasting designs

The exceptional durability and longevity of our cold forging die designs distinguish them. Throughout the design process, we use high-quality materials and implement stringent quality control measures to guarantee that the final product meets the highest standards. Utilizing our expertise, we are able to cut down on downtime, increase die life, and minimize wear and tear, resulting in significant cost savings for your manufacturing operations.

Conclusion

You may enjoy increased productivity, improved product quality, and lower manufacturing costs if you select our rubber molding die design services . You can rely on us to offer you cutting-edge, dependable, and high-performing die designs that are tailored to your particular cold forging requirements.

We serve across following Locations