- Home

- Upset Cold Drop Closed Die Forging Design

REQUEST A QUOTE

Application of closed die forging design And Other Techniques To Boost Productivity

We have presently focused on how to achieve maximum utilization of the forging hammer, which is usually underutilized in maximum cases. We have seen that it is possible to meet the ever-increasing demands of forging products if we bring about certain changes in the forging die design.

- Elimination of fullering step to reduce the cycle time and enhance the production rate.

- Complete utilization of the machine capacity boost productivity.

We are ready to help you with our forging die designing process that will aid in meeting your high demands for the products.

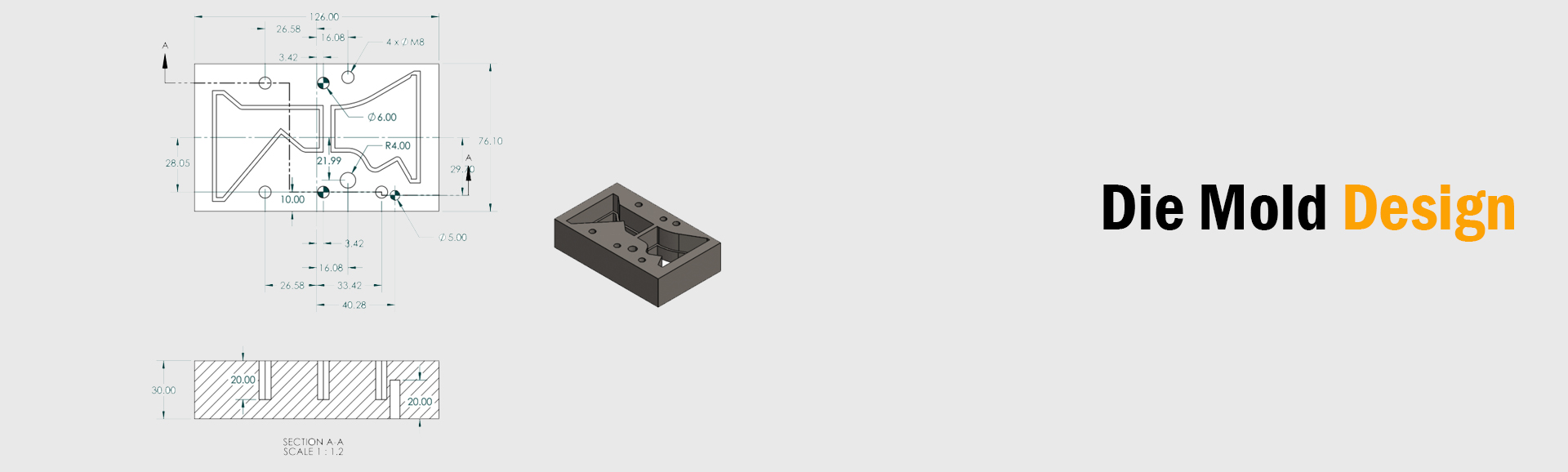

Attaining perfection through closed die forging design

We have been experimenting with the different types of forging procedures that will help to serve you better. We are currently concentrating on the closed die forging design where the two dies will move towards each other and cover the final product partially or wholly.

- Accuracy of the final form is maximum, for we incorporate the shape of the final product in the top or bottom die, just like a negative image.

- As it will come from above or below, the conversion of the raw material into the final product is perfect.

We are glad to inform you all that now, you can boost the production of the forged products, with maximum accuracy level!

Enjoy the benefits of upset forging die design

As we already said, we have always been planning to improve the ways of creating the products for our clients. That’s when we noticed that unique advantages are available if we apply the upset forging die design . In fact, the process turns out to be better than casting or welding.

- You can maintain the integrity of the raw material by application of heat in isolated sections.

- Optimization of grain flow properties helps in the superior fabrication of items maintaining the consistency of the shape.

For instance, if you forge a long bolt with a hexagonal head, the unbroken grain flow will always result in better work to the same item n comparison to the welding process using a hexagonal nut on the other end of that bar.

Improve appearance with cold forging die design

With so many procedures of die designs available in the industry, it is mandatory for us to be careful and logical in thinking about the right techniques to apply. The cold forging die design is applicable if you want a perfect surface finishing of the product.

Cold dimensional tolerance and the use of low-cost materials are the reasons why we can offer the service at an amazingly affordable rate. So it's time to avail of our drop forging die design and other designing techniques that will aid in better production of perfect products.

3d Cad Design Service: The best place provides extruder die design

Extruder die design assistance is provided by 3D CAD Design Service. In various manufacturing processes, such as plastic extrusion, where molten material is forced through a specially shaped opening to produce the desired product profile, extruder dies are crucial. We can provide you with a comprehensive and effective die design solution thanks to our cutting-edge CAD capabilities.

Precise Extruder die design

The extruder die designs that are both precise and individualized are created by our skilled design team using cutting-edge 3D CAD software. We can accurately model intricate geometries, incorporate intricate features, and optimize flow channels within the die by utilizing the power of CAD. Because of this, we are able to modify the design of the die in accordance with the particular needs of your manufacturing process, thereby guaranteeing that your extrusion procedure will operate at its highest possible level of effectiveness and quality.

Best Collaborating Service

We closely collaborate with you throughout the design process to comprehend your individual requirements and objectives. When designing a die that meets your exact requirements, we take into account things like the properties of the material, the specifications of the product you want, and the volume of production. We, one of the best closed die forging design manufacturers , can optimize the die geometry for improved material flow, decreased waste, and improved product quality thanks to our expertise in CAD designs.

We serve across following Locations