- Home

- Cavity Spaces Side Core Design Company

REQUEST A QUOTE

Create Mold Designs through the Core Spaces and Design

Core and cavity play an important function in the entire process of molding. The traditional casting method with the help of molding design is now initiating much less interest among the workers. Some of the workers are also not acquainted with the idea of core and cavity

Hence we will help you identify the core and cavity designs for better molding functions. With the understanding of the newer Core Spaces and Design , designers and technicians will make more casting

Discussing the Functions of Core Cavity Design

If you want to design any molding process or use it for any production process, you need to understand the core and cavity parts in more detail.

- The cavity represents the female part of the molding that handles all the external functions of molding, while the core is the male part of the molding where internal molding shapes are happening.

- Plastic parts for production can be a difficult scenario for molders, creating new design challenges.

- Hence we reached a point of understanding of the Core Cavity Design

Choosing the Right Company for Making the Molding Designs

Choosing the right company for making the molding products and assisting the manufacturing team in increasing the demand is a tiring job. Hence we are helping you to identify the right company for injection molding.

- Before you decide to choose any company, first see that the entire manufacturing process is well maintaining the injection molding process

- High capability power injection molding will help to produce a larger mass of materials compared to any other machine

- If you choose the Core Design Company , then look for core designing machines with high executing power.

The Architecture of the Core and Cavity Molding for Generating Parting Surface

The ideal Core Cavity Design is only possible with the help of the parting surface. The parting surface helps create a parting direction and lines for the core and cavity blocks.

- We should see that the parting edge is prominently classified to generate the parting surface.

- Specified extruded directions for the different groups in the partying line help form the core and cavity part more properly.

- We should always see that the experts should know about the differences between the parts of the injection molding machines

Advantages of Side Core Design for Pulling Mechanism

The advantages of Side Core Design are to it helps the pulling mechanism. The outer and inner holes of the plastic part are usually different from the direction of the opening mold; hence a movable side core helps to take out the plastic part with the hell of pulling mechanism.

Your Perfect Vision For Perfect Design: Core Design Company

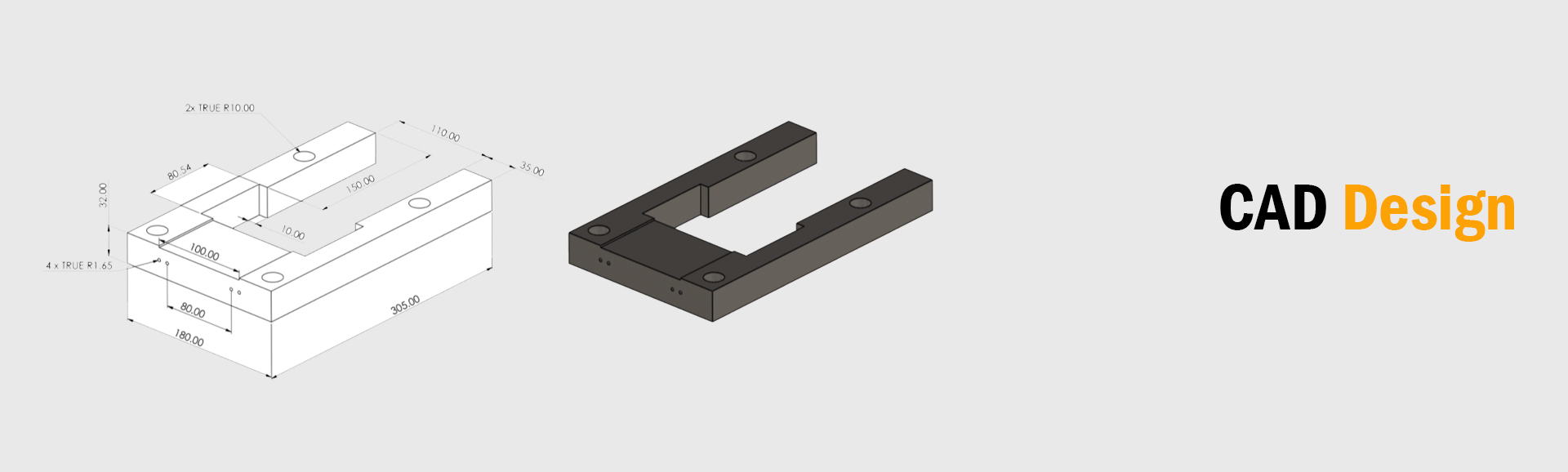

Welcome to Core Design Company, where we specialize in delivering top-notch 3D CAD services to turn your ideas into reality! At Core Design, we're dedicated to bringing your concepts to life with precision and creativity using innovative computer-aided design solutions.

Whether you require product design, engineering solutions, or architectural planning, Our Company is your reliable partner. Our skilled team is committed to exceeding expectations, ensuring that your projects are not only realized but surpass your vision. We prioritize simplicity and ease of use in our 3D CAD process, providing a seamless experience for our clients.

Experience the future of design with Core Design —where imagination seamlessly meets precision. Trust us to elevate your projects with our state-of-the-art 3D CAD services.

Our Skills in Side Core Manufacturing and Core and Cavity Design

Our excellent Catia Mold Design services at 3d Cad Design Service are suited to your unique needs. We ensure smooth and effective mold design procedures using our Core and Cavity Design knowledge in Catia .

Additionally, we are experts in producing Side Core Design, which enables you to maximize your manufacturing capabilities. Find out how your mold design tasks can be revolutionized by our complete offerings.

Catia Mold Design for Precision and Efficiency

We produce precise and effective mold designs with our Catia Mold Design services by combining the power of state-of-the-art software with the expertise of our staff. Utilizing this effective technology, we give you the ability to quickly construct intricate mold designs, increasing the overall productivity of your manufacturing operation.

Core and Cavity Design in Catia

An essential component of mold design is Core and Cavity Design in Catia , an area in which we specialize. We know the challenges in designing precise and useful core and cavity elements. The overall performance also increases with the capability of the team members.

To create top-notch core and cavity solutions that satisfy your particular needs, our talented designers take advantage of Catia's powerful features.

We assist you in lowering operating expenses and accelerating time-to-market by assuring ideal mold performance and minimizing manufacturing faults.

Side Core Design Manufactures for Enhanced Capabilities

We have a specialization in manufacturing side core designs in addition to the core and cavity design. Getting a side core design manufactures will improve the outcome in a drastic way. Molds with intricate features and undercuts often have side cores, which are essential.

Our talented staff is exceptional at creating side cores that let you precisely create complex pieces.

Through the use of Catia's extensive toolkit, we ensure a seamless incorporation of side cores into your casting designs, thereby increasing the company's production capabilities and product options.

Conclusion

We are aware that the needs for mold design vary depending on the industry. Our side core design manufactures services can be customized to meet your unique requirements whether you work in the automotive, aerospace, consumer products, or any other industry.

In order to fully understand your project objectives and ensure that the final mold concept is compatible with your production procedures and intended results, our team of professionals works directly with you.

We serve across following Locations