- Home

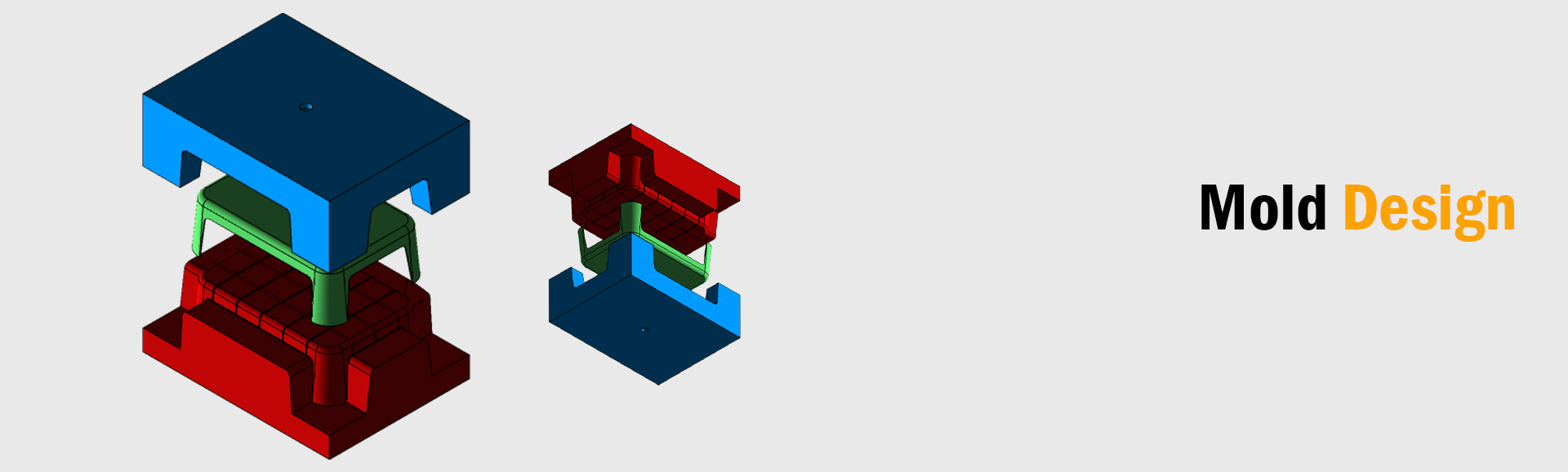

- Autocad Solidworks Mold Flow Simulation Report

REQUEST A QUOTE

Mold Flow Simulation Provides The Best Services Possible

The mold flow simulation is here to provide the much needed information regarding how well the mold will be filled during production. It will allow the design team and the engineers to see in case any area of the mold will not get filled completely with plastic. It forms a major part of the engineering and producing molded plastics for wider range of purposes. Molded products are in need of customized injections and should have a simulation done before producing the prototype as it increases the chances of that successful product.

Understand the simulation with solidworks mold flow :

Not all the managers or buying agents understand the procedure involving solidworks mold flow . This is one method of using advanced software and technology for simulating process of filling any part made using molded plastic.

- It will also focus on the packing and cooling of the said component

- It is mainly used as one diagnostic tool for detecting the potential problems with mold flow designs at early process stage

- The simulation will offer in-house engineers with visual representation of way in which mold will be filled

Major information with plastic injection moulding process flow chart :

Get in touch with the best team of experts for the best ever plastic injection moulding process flow chart services. The simulation of mold flow offers important information on how the mold will fill during protection.

- It will allow the design team and the engineers to see in case the mold will not be filled with plastic completely

- It will demonstrate where in the part, weld lines will develop and whether these points can be considered structurally sound

- Advanced simulation of the mold flow can further analyze coding lines and the effects as well

Simulation times and costs of flow moulding :

Conducting that mold flow simulation will allow the engineers to save time during the development process, which will cut the costs significantly. These financial savings associated with flow moulding will then be passed onto the company purchasing agents.

- It helps in boosting sales by presenting more affordable pricing to the buyers

- The simulation process is now able to save time in various ways

- The autocad mold flow will allow the product to be analyzed instantly to ensure it can be manufactured

The value of mold flow report to cover:

The mold flow simulation process will allow the in-house engineers to predict any of the potential issues associated with the quality. It will range from the improper draft angles to the flow lines of mold flow report. It will allow for that immediate adjustment before the time is spend working off the resources or design used to create it. So, check in with us for some quality help now.

We serve across following Locations