- Home

- Three 3 Plate Mould Design

REQUEST A QUOTE

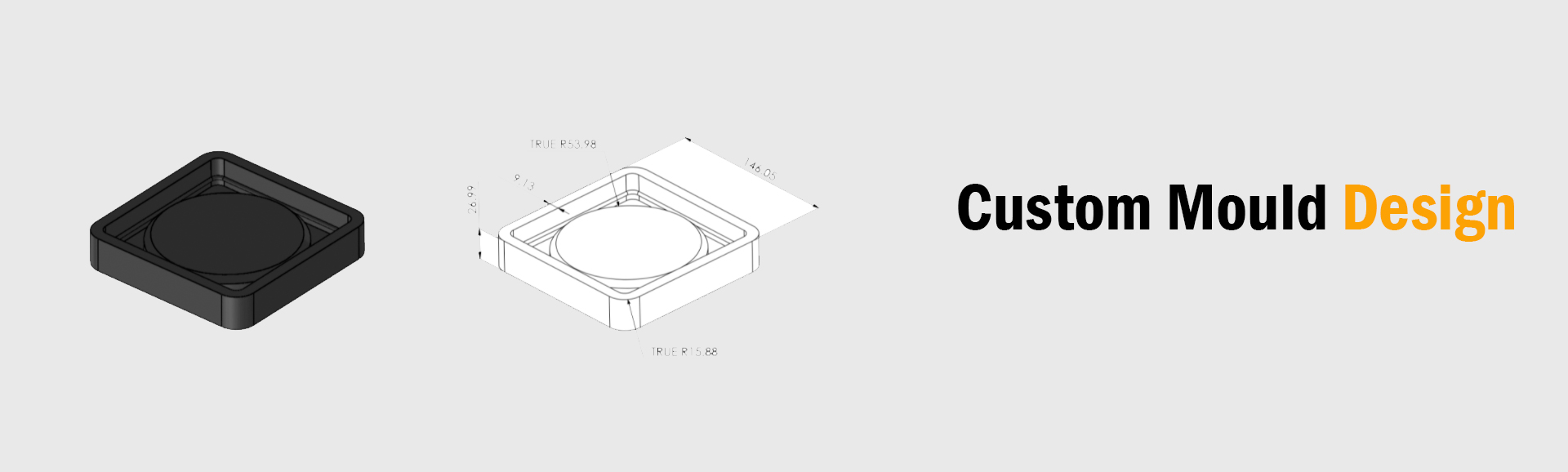

3 Plate Mould Design Ultimate Help As You Have Asked For

This might be the very first time when you are hearing of the term 3-plate mold. This form of mold is practically used when a section of the runner system is on any different plane to that of the injection location. The runner system for the three-plate mold will always sit on second parting plane, which remains parallel to the major parting plane. Then you have the second parting plane, which will enable the runners and spruce to be highly ejected whenever the mold is opened.

Get the best 3 plate mould design from us:

In case you re aiming for that 3-plate mold option, then we welcome you to get the 3 plate mould design from our side. We will be offering you with the mold’s design only after learning what your company is looking for.

- We will be offering you with top-notch quality response, which is hard to get from anywhere else

- Even the prices of our items are over the affordable range to make it easily reasonable

- Choose us and there is no need to look for a secondary helping hand anymore

Quality of the three plate mold design :

It is one of the major reasons for you to get hold of our side while focusing on the three plate mold design . We will ensure better quality, which is hard to get from anywhere else.

- Just because you are going to get higher quality that doesn’t mean you need to pay more

- We offer affordable services, which are hard to get from anywhere else for sure

- In case you are a novice and looking for premium quality help, we are here for you

The movable plate of the 3 plate mold design:

There are some movable parts associated with the 3 plate mold design and learning about that beforehand will help you with its functionality more.

- The runner or the stationary plate or the clamping plate remains attached to fixed or stationary platen

- The floating or the center plate is linked to two of the other major plates

- Then you have the moving or the front cavity plate, which is attached to the moving platen to the said machine of your choice

Join us now for 3 plate mould design :

So, next time you are out in the venture to look for the best team working on 3 plate mould design, make sure to give us a call. We have been associated with this field for a long time and know what you have been looking for in the 3-plate mold design. So, offering you with the best result won’t be that tough of a deal for us to handle over here.

Our 3 Plate Mold Design Services Can Help You Increase Efficiency and Precision.

Our business offers complete mold design services that are especially suitable for injection moulding mould design .

Thanks to our knowledge and cutting-edge technology, we provide creative solutions that maximize productivity, accuracy, and user involvement within the injection molding process.

Unlocking Potential with 3 Plate Mold Design

Injection molding, the 3 plate mold design services offers extraordinary versatility and complexity. It enables the development of complex designs, the incorporation of numerous features, and the successful ejection of molded components.

Businesses can increase production rates, reduce cycle times, and improve product quality using 3-plate mold design services.

Our Expertise in 3 Plate Mold Design Services

Deep knowledge and skills in 3 plate mold design are held by our team of talented engineers and designers. To produce ideal procedures and satisfy the most rigorous criteria, we use cutting-edge software and simulation techniques.

We make sure that every mold design we produce exceeds expectations by paying rigorous attention to detail and putting a strong emphasis on creativity.

Optimal Mold Design Improves User Engagement and Productivity

The production process is optimized while also decreasing complexity and streamlining operations with the help of our 3 plate mold design services.

We enable quicker production cycles and increase efficiency by including adequate gating infrastructure, cooling methods, and ejection mechanisms. We know that practicality and aesthetics are essential to the success of injection-molded items.

Our mold layouts are meticulously designed to provide the best possible functionality of the item, longevity, and aesthetic appeal.

Conclusion

Join us to improve user engagement, streamline injection molding, and produce better outcomes. Our area of expertise is in offering top-notch solutions to creating injection molding mould design tools that maximize productivity and guarantee accurate manufacture.

We serve across following Locations