- Home

- Thick Wall Runner Lifter Boss Rib Design Injection Molding

REQUEST A QUOTE

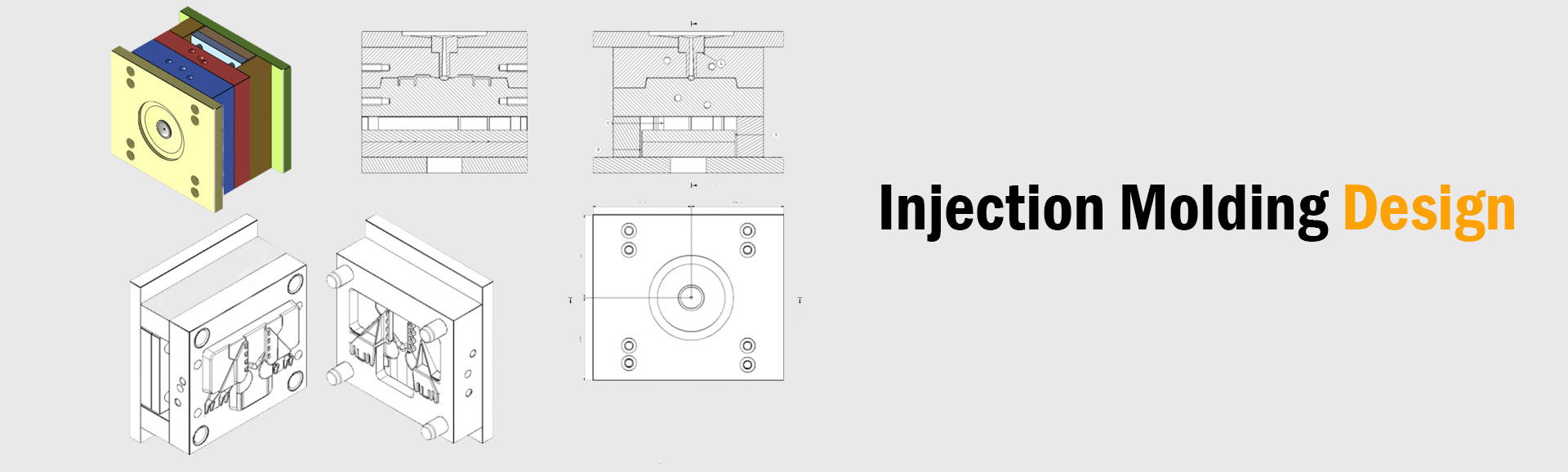

Strengthening a Plastic Injection with Rib Design Injection Molding Design

The concept of plastic injection mold to hold up the large hold is not that difficult to understand as carrying something requires much stronger strength. Hence, we are using some extra parts to hold the extra load.

With the help of Rib Design Injection Molding , we are able to hold a larger load. By attaching a rib with the design part, the strength increases by reducing other defects. The more the strength, the more the function of carrying any materials will be.

Designers to Increase the Strength with Thick Wall Injection Molding

- Designers are constantly trying to improve the thickness of the wall, so more stiffness and strength are there to hold the plain molded part.

- But we make sure that the thickness of the wall increases with the help of ribs, so designers are trying Thick Wall Injection Molding to make it a bit effective and reliable.

So if you are also confused about choosing the right material for your project, try to consider taking the thickness of the wall through the

Injection Mold Lifter Design High Tech Technology with the Boss Injection Molding

- As the Boss Injection Mold is constantly using the field of the industrial and commercial sector to produce work with much hassle-free

- These kinds of machines are usually there in the injection molding Design.

- With the use of boss injection molding, we ensure that there is a strong connection with all the parts and hence reduce the cosmetic defects.

- If you are looking for a molded boss, you should always look for the strength, material, and molding design.

Considering the factors before using Injection Molding Boss design

As injection molding plays an important role in fabricating any plastic parts, it also requires many tools and machines to make it’s part more appropriately

There is a wide variety of applications in the different fields, varying from medical equipment to houseware parts, increasing day by day. So we need to consider all the designing tools and Specially Injection Molding Boss Design , to cater to all the customers' needs. This machine attached to the molding parts helps the designers to produce more work reacted to the demand in the market.

Replacing the Cold Runner System with the Runner Design Injection Molding

From the tradition, the injection mold has used the cold Runner Design system to cater to the entire manufacturing process. But since this kind of system takes more time to give the output, we choose some new processes like the Runner Design Injection Molding .

This helps make the work easier, reliable with no flow rate issue, and gives more time for the process to cycle

Unleash Innovation with Our Cap Mould Design Expertise

Welcome to 3d Cad Design Service, a reputable bottle cap mould design company committed to offering top-notch cap mold design services. We provide cutting-edge solutions that adhere to the highest standards of functionality and quality thanks to our wealth of experience and state-of-the-art technology.

What Makes Our Cap Mould Design Services the Best?

Precision and Customization: At 3d cad design service, we are aware that each cap design is distinctive. To create exact and personalized cap mold designs that precisely meet your needs, our talented team of designers uses cutting-edge 3D CAD modeling.

Improved production Process: We carefully develop the designs of our cap molds to improve the production process. By taking into account elements like material flow, cooling, and ejection, we guarantee effective manufacturing, reduce cycle times, and boost productivity.

Production of High-Quality Caps: We are dedicated to providing High-Quality Bottle Caps. Our cap mold designs prioritize dimensional precision, homogeneous wall thickness, and smooth surface finish, producing exceptional caps that meet or surpass industry standards.

Our team is innovative and flexible, keeping up with the most recent developments in the field. We make use of our knowledge to offer unique cap mold designs that improve the functionality, appeal, and market competitiveness of the product.

Consider 3d cad design service for Your Needs in Cap Mold Design

Unmatched skill: We bring years of knowledge and skill to every project as a top cap mold design company. Our staff has successfully created caps for a variety of sectors, giving us the experience necessary to meet any task.

Collaboration: We adhere to a collaborative philosophy and work closely with our clients to fully grasp their unique needs. Our team works closely with you to realize your vision for the end product throughout the design process.

Modern Technology: To evaluate and improve cap mold designs,3d cad design service uses cutting-edge 3D CAD software and sophisticated simulation tools. We can deliver precise designs, cut down on revisions, and accelerate time to market because of this technology.

Expert Cap Mould Design Services at Your Service

3d cad design service is the best option when it comes to cap mold design. We stand apart from the competition thanks to our dedication to innovation, accuracy, and client happiness. Make the first step towards improving your bottle cap mould design company by getting in touch with us right now to discuss your cap mold design requirements.

Revolutionise Your Moulding Process with 3 Plate Mould Design

We are a top supplier of creative solutions for 3 plate mould design , focusing on the practical and cutting-edge 3 plate mould design method.

We provide comprehensive services that modernise the moulding process for many sectors thanks to our knowledge and cutting-edge technology.

Advantages of 3 Plate Mould Design

Utilise our service for 3 three plate mold design to benefit from unmatched precision and effectiveness. Comparing this modern method to conventional mould designs, there are many benefits.

We increase the complexity and flexibility of the moulding process by inserting an additional plate. Our method enables the production of complex designs and the integration of numerous aspects, producing goods of superior quality.

Our Experience in 3 Plate Mould Manufacturing

At 3d Cad Design Service, we have a group of talented engineers and designers with a wealth of knowledge in 3 plate mould manufacturing . We make use of their ability to develop specialised moulds that are suited to your particular needs.

Our moulds provide outstanding performance and lifespan due to our attention to particulars and dedication to quality.

How Our 3 Plate Mould Design Service Boosts User Engagement

- You can create designs that were previously thought to be unachievable with the help of our 3 plate mould design service.

- The additional plate enables the development of intricate shapes, allowing you to create distinctive and captivating goods that enthral your customers.

- Our three plate mold design the moulding procedure, leading to shorter cycle times and higher output.

- You can fulfil strict production deadlines and cut down on time-to-market by optimising the manufacturing process, providing you with an unfair advantage in the market.

- Our three plate moulds' accuracy and precision guarantee a constant, high-quality output.

- Your finished products will have an outstanding finish thanks to eliminating flaws and reducing parting lines, increasing consumer satisfaction and your company's credibility.

- Our 3 plate mould manufacturing service is very advanced, but we still work to deliver affordable solutions.

- Our solution helps you save material and operating costs while increasing output effectiveness and waste reduction, enhancing your return on expenditure.

We serve across following Locations