- Home

- Compression Mould Design Company

REQUEST A QUOTE

4 Reasons Why compression mould design Has Become the Trendsetter

Using uncured rubber or plastic has been a regular part and parcel of the compression molding process where we are using custom machine molds to produce the form parts.

- We have t place the material into the open mold cavity

- close up the mold

- apply heat and pressure and then,

- Solidify once the material takes up the right shape of the desired component.

Now, many of our clients ask us why it is better to opt for compression mould design when there are other procedures for casting or molding. So we have planned to notify all of you about some of the unparalleled advantages of the process.

1.Go simple with compression mould design

The process of molding can already have many complications. Why would you like to add to the complications when you have a straightforward alternative, which is better than all the other manufacturing and molding procedures?

We find it easier to make some of the parts and forms using the compression die design for it reduces production time and cost simultaneously.

2.Lower tooling costs for compression die design

If you compare it with the process of injection molding, you will find that our compression molding process won't require much special equipment or expensive and complex tooling. As a result, our compression mold design company is ready to use the basic tools and equipment, thus reducing the capital investment significantly.

- The process is labor-intensive, but we have the skilled personnel to handle the work aptly.

- The wear and tear of the molds during the operations is lower.

- No need for an elaborate maintenance process.

Thus, please don’t roll your eyes when we quote a really low price for the compression mold design .

Expert Compression Mold Designer

Elevate your manufacturing processes with us, a leading compression mold designer. Our dedicated team of experienced designers is committed to delivering top-tier solutions tailored to your unique needs.

We take pride in our proficiency in 3D CAD technology, ensuring precision and efficiency in every mold design project. Our innovative approach combines creativity and technical prowess to craft molds that meet the highest industry standards.

Whether you operate in automotive, electronics, or other sectors, our compression mold designs are customized to enhance your production capabilities. We prioritize collaboration with our clients to understand their specific requirements and deliver solutions that exceed expectations.

Choose our company for cutting-edge compression mold design that integrates seamlessly with 3D CAD technology. Experience the difference in quality and precision with our expert services.

Your Trusted Compression Mold Design Company

Welcome to us, your trusted partner for cutting-edge compression mold design company. Our team of skilled professionals specializes in crafting precision molds using state-of-the-art 3D CAD technology.

We understand the critical role that efficient mold design plays in manufacturing processes. Leveraging our expertise, we deliver tailor-made solutions to meet the unique requirements of your projects. Our commitment to excellence ensures that your compression molds are not only designed with utmost precision but also optimized for performance and longevity.

With 3D CAD at the core of our design process, we guarantee accuracy and efficiency in every mold we create. Our innovative approach allows for seamless collaboration, rapid prototyping, and effective problem-solving throughout the design phase. Trust us for compression mold designs that redefine industry standards and elevate your manufacturing capabilities. Experience the future of mold design with our expert team and cutting-edge technology.

3.Ideal for producing large parts

It is not necessary that all our customers will come with demands to make small parts. As the process of compression molding allows the loading of the material directly into the cavity, we can relax the weight limitations to a considerable extent. But we have to be extra cautious as compression die designer when you have specifications for the size or pressure capacities of eh product. Overall, we are all set to handle manufacturing the bigger parts.

4.Multicolor molding from compression die designer

As we have been using the vertical compression press for a long time, we have been able to offer the right approach to the particular tooling necessary for insert molding and dual-color molding. Being the most affordable compression mold designer, we have come up with this innovative approach that won't make us use the high-cost special equipment even for making the multi-colored products.

We have inspired many clients to think bigger, even with limited financial capacities. Our approach will be beneficial to you in many ways.

3d Cad Design Service: The top place for getting compression molding die design

The compression molding die design services provided by 3D CAD Design Service are effective and precise, and they are tailored to the specific requirements of manufacturers in a variety of industries. Our skilled design team creates high-quality compression molding dies using cutting-edge software for 3D modeling and simulation to guarantee the best possible product outcomes.

A comprehensive approach to compression molding die design

The client's requirements are the foundation for our comprehensive approach to the design of compression molding dies. To gather all necessary information, including part specifications, material properties, and production volume, we work closely with our clients. Because of this, we are able to design a blow molding die head design that is both cost-effective and machinable while still meeting the exact dimensional and functional requirements.

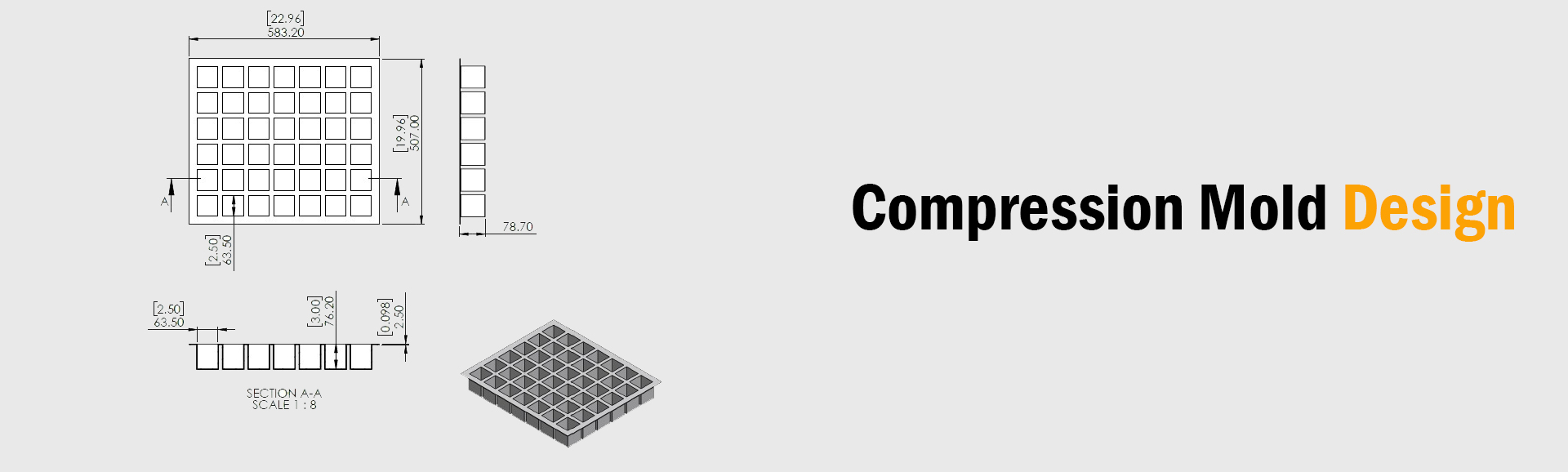

Precise Model of Design

A precise three-dimensional model of the compression molding die is created by our skilled designers using cutting-edge CAD software. Every aspect, including the design of the cavity and core, the parting line, the runner and gating system, the cooling channels, and the ejection mechanism, receives our undivided attention. Because of this, the design of the die can be improved to ensure consistent part quality, minimal waste, and effective material flow.

We serve across following Locations