- Home

- Unscrewing Slide Design Side Core In Injection Moulding Engineering

REQUEST A QUOTE

Applying side core in injection moulding To Achieve Perfection in Applications

Business owners all across the globe are searching for ways to reduce the cost of manufacturing to increase profit. However, as most of the costing depends nowadays on the injection molding process, you have to depend on us completely for any cost-reducing ideas. The application of side core in injection moulding has become our latest revolutionary technique that has simultaneously reduced cost and prevented loss.

Mechanism of side core in injection moulding

Any times, we have faced problems in ejecting the plastic parts, as the inner and outer holes or eh undercuts of the plastic parts are different from the direction of mold opening. In such cases, we are applying an action that will transform the undercut part of the molded side hole into a moveable core. Taking out the moveable core before the plastic pat is an art of injection mold engineering that we have mastered.

Making the unscrewing mold design

One of the unique types of injection molds is the unscrewing mold that many of our clients need regularly. Common types of products that we make using the unscrewing mould design include:

- Prescription medical bottles

- Bottle and milk caps

- Crews, nuts, and bolts. Medical supplies

- Showerheads and sprinklers

- Lids of Conditioners and Shampoos

And with such assignments, we receive the responsibility of checking a number of factors carefully. Let's look into those factors.

1.The volume of unscrewing mold design

As the volume of our manufactured product will determine many aspects of your final product, we have to maintain complex validations for unscrewing molds. We have been performing well so far with the accuracy level of the injection mold slide design .

2.Checking the thread count as an injection mold designer

Based on the final product, our number of threads in the process will change. While water bottles won’t require a high thread count as these are lightweight and can be easily removed, the plastic part under the hood of a car will need a higher thread count. Being the expert injection mold designer, we have to determine the number of threads that we will use for the purpose. It will play a significant role in the final production cost.

Tiny Details, Big Impact: Our Injection Mold Designer

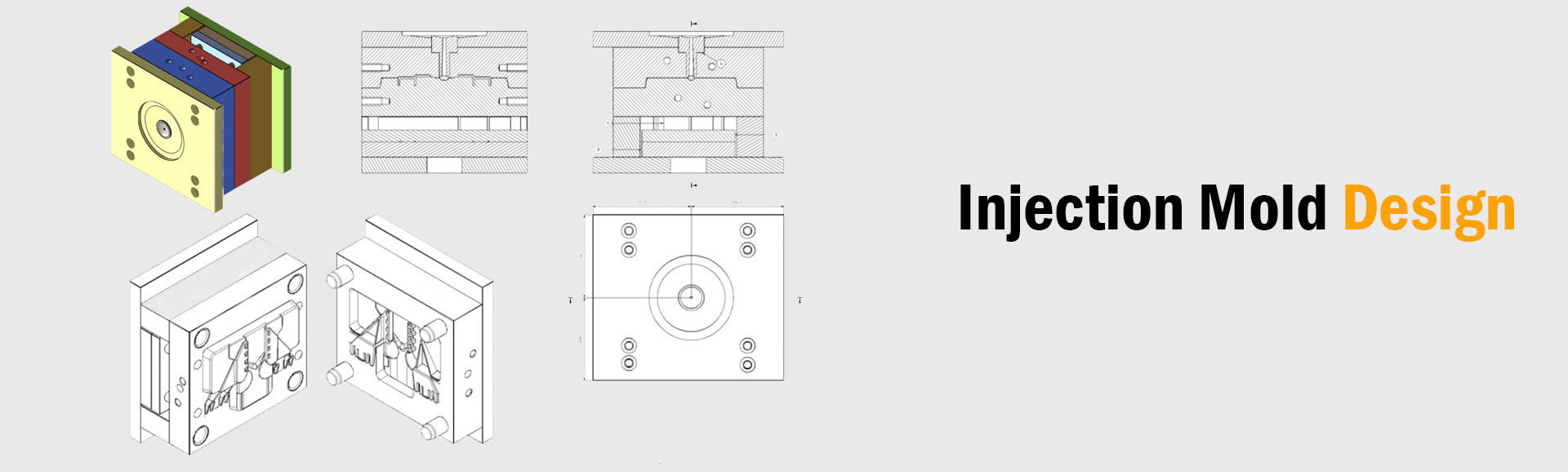

We're your go-to experts for injection mold design, and we're bringing cutting-edge 3D CAD technology to the table. What does that mean for you? It means we're turning your ideas into reality with mind-blowing precision.

Our team of mold maestros is all about pushing the limits and making your projects shine. With 3D CAD, we're not just designing molds; we're creating perfection. This tech wizardry ensures your end products are top-notch, every single time.

Why choose us? Our injection mold designer are pros who know the ins and outs of different industries. They're like superheroes, but for mold design. They pay attention to the tiny details, making molds that supercharge production efficiency and product quality.

Thanks to 3D CAD, we're not just designing in two dimensions; we're living in the future. It lets us predict and solve problems before they even show up, making everything run like a well-oiled machine.

So, if you want injection mold designs that redefine awesome, come to us. We're not just experts; we're experts with 3D CAD magic up our sleeves, making your projects smoother and better than ever.

3.Ease of removal in hand injection mold design

Automation is not always the key to controlling the chief elements of mold design. When we use hand injection mould design, we can control the ease with which a user will be able to open the unscrewing mold. While the lid of a water bottle should come off easily, the lid of a medical container must be difficult to open.

Our understanding of the unscrewing injection mold design makes us the leading company in designing the perfect unscrewing molds. This way, our clients always get the best product from us.

Top-quality Silicone Mold Design

3D CAD Design Service is the one company that stands out from the rest when it comes to high-quality silicone mold design . We give top-notch results for all of your silicone earth design conditions thanks to our moxie and slice-edge technology.

Accuracy and advancement in silicone mold design

The 3D computer-aided design configuration administration is known for its obligation to accuracy and advancement. We have a platoon of professed contrivers who have worked in the assiduity for times. The rearmost 3D CAD software is used by our professionals to produce intricate and precise silicone mold designs that meet our customer's exact conditions.

Meet your requirements

The 3D CAD Design Service can meet your requirements, no matter if you are in the manufacturing assiduity or just a layman who wants to make molds that are just right for you. We are aware of how crucial a well-designed mold is to produce flawless products. We can help you turn your ideas into reality by utilizing our expertise.

Using advanced 3D modeling techniques, the 3D CAD Design Service, the best plastic mold engineering company creates detailed digital prototypes of your silicone molds. You can visualize the finished product before it is made with these prototypes, reducing errors and ensuring a smooth production process.

We serve across following Locations