- Home

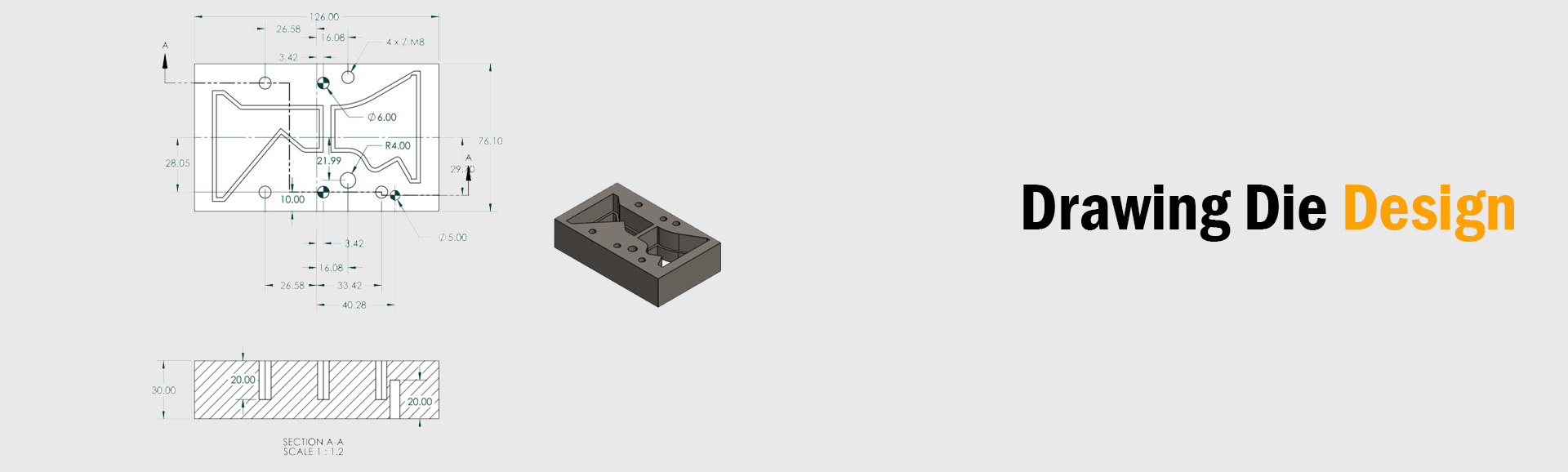

- Drawing Stamping Compound Die Design

REQUEST A QUOTE

Significance of Accurate drawing die design For Production

Are you searching for a company that can assist you in making cup-like objects? Your search ends with us, as we have got one of the most expert teams with us for drawing die design . For those who are hearing the term “drawing die” for the first time, let us elaborate a bit.

Explaining drawing die design in

When we use sheet metal for making a cuplike article, we have to push into the metallic sheet by a punch and simultaneously prevent the wrinkle formation using a blank holder that will firmly hold the outer edge of the metal. The process is not as straightforward as it might seem. Hence you have to be specific about choosing the professionals. We have come a long way in the successful execution of die drawing.

Factors affecting drawing die design

One of the many parameters that impact the draw design in the case of cup drawing is the draw ratio or D/d, where D stands for blank diameter and d stands for punch diameter. Typically, the punch diameter should be the inside diameter of the completed article.

- Our team will perform standard laboratory tests to evaluate the relationship. We have the necessary toolset, which is a typical one with a fixed diameter and a flat-bottom punch.

- We will now position blanks of marked diameters in the toolset and draw the round cups.

- Now, we will keep increasing the blank diameter with small increments until we reach a diameter that will fail to produce a fully drawn cup devoid of splits or necks.

We can deduce the limiting draw ratio or LDR by diving the largest blank diameter by the draw-punch diameter.

Multiple cutting with compound die design

When we have to perform more than one cutting operation in the dies, we like to call them the compound die design . There will be piercing, blanking, and drawing in the same single station, and the completion will be within one press cycle. How do you plan to utilize it in the manufacturing operations? Let us explain vividly.

- A single tool will aid in mass production without discrepancies in design and good geometrical tolerance.

- A durable tool will help you die and punch over an extensive period.

- You can eliminate human resources with the automation of the process and boost the production rate.

The die design will be a one-time investment that will help you reap benefits over the years.

Assembling is important

Even when we are using stamping die design , we are always maintaining focus on the assembly of the tool. If our die design has any glitch, we cannot produce in bulk as possible with the correct design and execution.

High-quality drawing compound die design services

When it comes to high-quality drawing compound die design services , one provider stands out from the rest, and that is 3d Cad Design Service. With our expertise, precision, and dedication to customer satisfaction, we are the go-to choice for businesses seeking top-notch designs.

Cad designers with expertise in drawing compound die design services

At 3d Cad Design Service, our team of skilled CAD designers possesses extensive knowledge and experience in creating complex compound die designs. We understand the intricate nature of compound die design and employ state-of-the-art software and tools to deliver exceptional results.

We Deliver Unique Requirements

One of the key strengths of our stamping mold design company is its commitment to understanding the unique requirements of each client. We ensure that the final design is perfectly aligned with the intended application by working closely with their customers to gather specific specifications. Our team is prepared to handle any project, big or small, whether it's a manufacturing operation or a small project.

We Use Advance Techniques

With a focus on accuracy and efficiency, 3d Cad Design Service utilizes advanced simulation techniques to validate and optimize the compound die design before production. This meticulous approach helps identify potential issues and enables them to make necessary adjustments early in the process, saving time and resources.

We serve across following Locations