- Home

- Gravity Die Casting Tool Hpdc Die Design

REQUEST A QUOTE

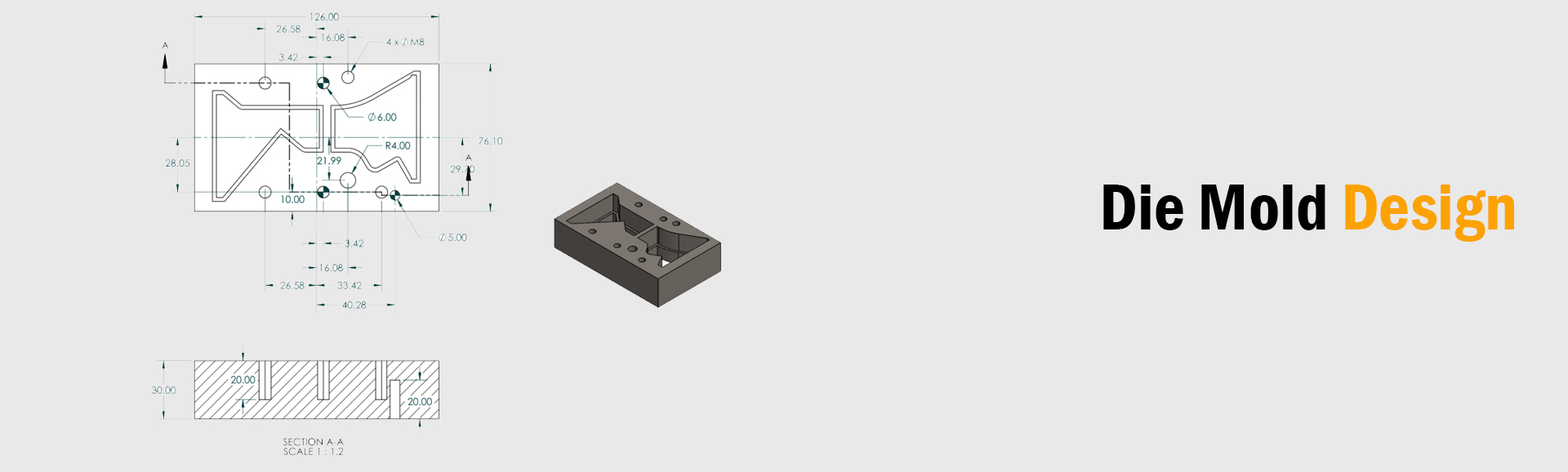

Overcoming The Challenges of hpdc die design Using Scientific Ways

Tooling service is an important aspect of the die casting procedure. We are glad to present our precise tooling service with high tolerances. If you are trying to achieve complex product shapes, we are here to help you with the advanced hpdc die design .

Dimensional accuracy is essential when you have the blueprint of a complex design. We have the most flexible procedures necessary for tooling construction. Provide us with your requirements, and we will adapt to individual demands.

Problem-free gravity die casting tool design

We specialize in designing and constructing products through Gravity die casting or Permanent Mould Casting. The gravity die casting tool design is repeatable and aids in the production of dimensionally accurate, medium run, non-ferrous castings, mostly in alloys of zinc, Aluminum, and Bronze.

Complete customization through casting die design

Our company believes that the needs of every industry are unique, and we cannot satisfy our customers if we don’t offer personalized designs.

- We analyze the type of performance you need and get rid of unnecessarily think wall sections. It will make the product lightweight, without compromising its functionality of the product.

- Internal tears cab cause obstruction in metal flow owing to shrinkage defects that will also induce stress concentration. That is why we try to use pockets in die casting tool design that will make the cross-sections thinker, but with constant monitoring to avoid shrinkage inconsistencies.

- We are also ready to use drafts that will introduce slight taper on cavity sides. These aid in the easier release of the casting from the die.

We are constantly improvising the methods to follow the appropriate procedure of die casting to help the construction of your desired products.

Avoiding sharp angles in a die casting die design

The significance of our scientific planning is apparent in the way we avoid the sharp angles in the molds. Such sharp angles can actually cause high thermal gradients. It will hamper the dissipation of heat in the die casting mold design .

- Sharp re-entrant angles create hotspots.

- Differential cooling rates can cause distortion and shrinkage tears owing to sharp corners.

- This is where we excel using our years of extensive experience.

Gradual section changes in casting die design

Section changes are sometimes an unavoidable part of your project. Hence,e instead of avoiding the sections, we will concentrate more on blending the sections of the casting die design with tapers that will reduce the stress concentrations.

Here will be no turbulence in the metal flow rate as we ensure that the feeding in the section is consistent. We would like to solve further inquiries about die casting die design if you ate ready to check out the next level of die casting designs.

Relation Between Efficiency and Cutting Die Design

The design of the cutting die determines how efficient it is in its job.

The experts at 3D CAD designs believe that the efficacy and functionality of the die depend on the design. Therefore, whether it is for cutting die design or any other, we are the one-stop solution for most manufacturers.

Whether the process is manual or automated, we ensure that our cutting die design will fit into any application.

The Efficacy of Cutting Die Design

When the cutting die is designed by us, users can rest assured about its optimal efficacy. Whether it is used for a softer material or a more robust variant, we have a solution for any need in our extensive range of mold and die design.

Manufacturers look for use when it comes to mold designing because they know that we can design a die for making paper clips or paper or for other complex machinery components.

We ensure that the edges of the cutting die are the sharpest so that it can take on a heavy workload and complete the task quickly with absolute precision and efficacy.

Our die design is entirely different from the others, irrespective of the material in question. This makes us stand out from our closest mold and die design competitors.

Working Process

During the process of aluminum die casting mold design , we focus mainly on the working process, among others.

It includes precision and attention to minute details to make the complex design process look simpler.

Our work typically relies on specific aspects, such as:

- The material used

- The type of machines the die is to be integrated and

- Other information related to the pattern, stripping, and other user specifications.

This also adds to the efficiency of the die because we can implement precision techniques in aluminum die casting mold design . We understand that die cutting is not an easy task. It needs meticulous skills and expertise, which we and the professionals associated with us have in abundance.

We all strongly believe that it is the design of the die that makes it great. Take a look at some of our great die designs by visiting our website. Partner with us to enhance your business productivity.

We serve across following Locations