REQUEST A QUOTE

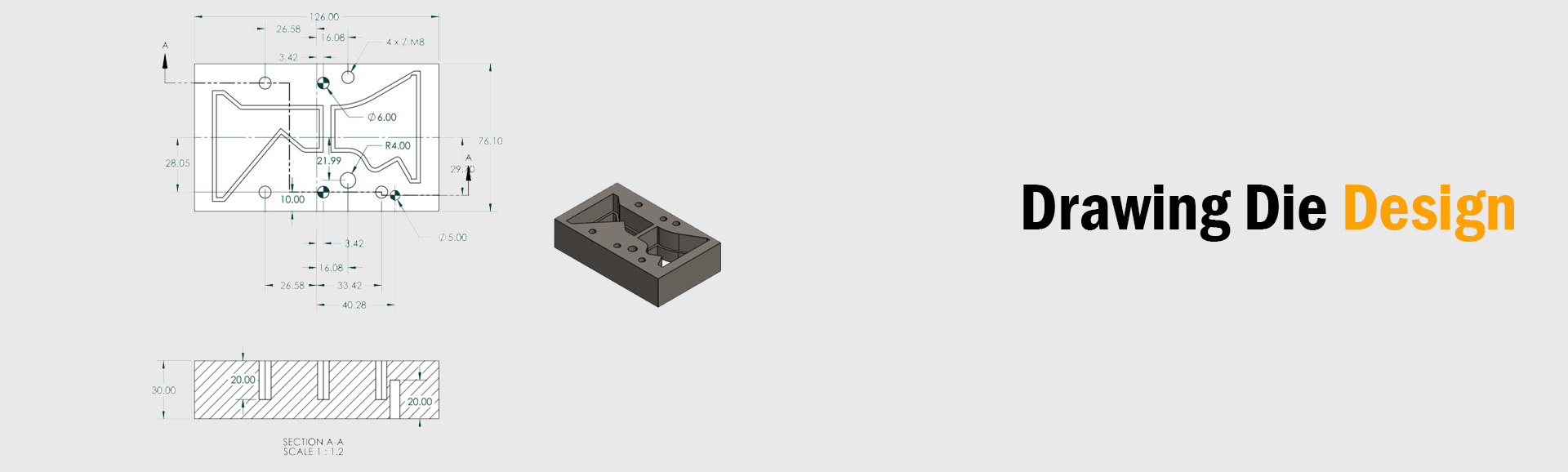

Role and purpose of drawing die design in Labrador City, NL?

- Mining Efficiency: Die design, optimizes mining efficiency by ensuring precise extraction of raw materials, reducing waste, and enhancing resource utilization.

- Material Quality: It plays a crucial role in maintaining the quality of extracted materials, contributing to the production of high-grade metals and minerals.

- Cost Reduction: Efficient drawing die design in Labrador City, NL minimizes production costs by streamlining the extraction process, reducing downtime, and enhancing overall operational efficiency.

- Tool Longevity: Proper die design extends the lifespan of mining tools, lowering maintenance and replacement costs while improving sustainability.

- Safety Enhancement: The design considerations prioritize worker safety, minimizing risks associated with the extraction process and creating a safer working environment in Labrador City's mining operations.

Key components and functions of compound die design in Labrador City Nl

Compound die design in Labrador City, NL involves crucial components and functions tailored for efficient manufacturing. The die comprises two or more operations within a single tool, streamlining the production process. Its key components include the die block, which holds the cavity and punch, ensuring precise shaping of materials. The punches and cavity work in tandem to cut and form the desired product. The stripper plate aids in ejecting the finished part from the die. This design enhances productivity by minimizing downtime and tool changes, ultimately reducing manufacturing costs. It plays a crucial role in optimizing production processes and promoting economic sustainability, especially in industries where operational efficiency is of paramount importance.

How Does Stamping Die Design in Labrador City, NI contribute to efficient Metal Forming Processes?

Efficient metal forming processes are significantly enhanced through meticulous stamping die design in Labrador City, NI. The thoughtful planning and execution of die design play a pivotal role in streamlining manufacturing operations. By optimizing the design, manufacturers can achieve precise and repeatable metal shaping, minimizing material waste and production time. This careful consideration ensures that the stamped components meet stringent quality standards while maximizing overall efficiency. The synergy between skilled die design and metal forming processes not only enhances productivity but also contributes to cost-effectiveness, making the manufacturing landscape more sustainable and competitive. As a result, die design becomes a cornerstone in the successful realization of efficient and reliable metal forming processes in this industrial setting.

If you're in need of top-notch drawing, stamping, and compound die designing services, look no further than our company's 3D CAD Design Service. We specialize in providing comprehensive solutions tailored to meet your specific requirements. Our team of skilled professionals is committed to delivering precision and innovation in every project. Whether you're seeking detailed drawings, efficient stamping die designs, or compound die solutions, we've got you covered. With a focus on quality and client satisfaction, we ensure that you receive customized and reliable support for all your designing needs.