REQUEST A QUOTE

Fundamentals of Rubber Moulding Die Design in Northwest Territories

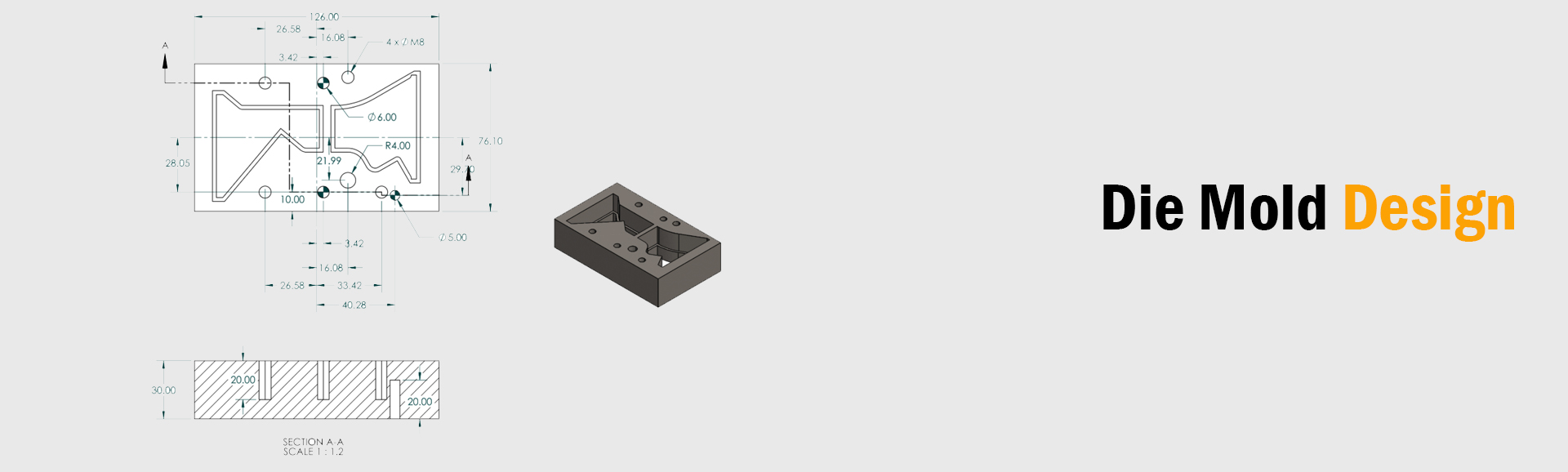

Mastering the fundamentals of rubber moulding die design in Northwest Territories is paramount, where precision meets innovation. In this specialized field, the design of moulding dies plays a critical role in shaping rubber products. Understanding the material properties, mold flow, and tooling intricacies are fundamental. Designers delve into considerations such as cavity design, gate placement, and parting lines to ensure optimal results. Attention to detail is crucial for creating moulds that withstand the rigours of production. In the Northwest Territories, where quality is paramount, a solid grasp of rubber die moulding design fundamentals is the cornerstone for crafting durable, high-quality rubber products.

Significance of Molding Die Design in Northwest Territories

- Precision Production: Molding die design in the Northwest Territories is pivotal for achieving precision in rubber product manufacturing.

- Material Efficiency: Strategic die design minimizes material wastage, optimizing resource utilization and reducing costs.

- Durability: Well-crafted molds enhance the longevity of production tools, ensuring consistent and durable performance.

- Complex Shapes: Die molding design facilitates the creation of intricate rubber product shapes, meeting diverse industry demands.

- Consistency: Accurate design ensures consistent product quality, vital for meeting stringent standards in the Northwest Territories.

- Efficient Production: Streamlined die designs contribute to efficient production processes, enhancing overall manufacturing productivity.

- Economic Impact: Robust die design directly impacts the economic viability of rubber manufacturing in the region, fostering growth and sustainability.

Best Practices for Mould and Die Design in Northwest Territories

Adhering to best practices in mould and die design in Northwest Territories is crucial for efficient manufacturing. Begin by understanding specific project requirements, considering material compatibility, and using computer-aided design (CAD) for detail and precision. Ensure proper cooling and ventilation systems to enhance the moulding process. Implementing robust quality control measures guarantees the production of high-quality dies. Working closely with suppliers for reliable materials and staying updated on industry advancements. Prioritize worker safety with ergonomic designs and comprehensive training. Regular maintenance and monitoring contribute to prolonged tool life and consistent performance. Following these best practices fosters a productive and sustainable mould and die design process in Northwest Territories.

Environmental Considerations in Die Mold Design in Northwest Territories

Integrating environmental considerations into die mold design in Northwest Territories is vital for responsible manufacturing. Opt for sustainable materials and processes to minimise ecological impact. Emphasise energy efficiency in the design, employing techniques such as optimised cooling systems. Select materials that are eco-friendly and recyclable to reduce the overall carbon footprint. Strive for modular designs that allow for easy disassembly and maintenance, promoting longevity and reducing waste. Stay informed about environmentally friendly technologies and implement them when feasible. By prioritising eco-conscious choices in die mold design, businesses contribute to a greener and more sustainable manufacturing landscape.

For precise and customized die and mold design solutions, your search ends with our company 3D CAD Design Service. We specialize in crafting tailored designs that meet your exact specifications. Our team leverages advanced technology to ensure precision and efficiency throughout the design process. With a focus on customer satisfaction, we work closely to understand your unique requirements and deliver solutions that exceed expectations. Trust us for comprehensive and reliable services, backed by expertise and a commitment to excellence. When you choose us, you're opting for top-notch quality and innovation in die and mold design.