REQUEST A QUOTE

Innovative Solutions of Plastic Die Design in Clarksville Town, In

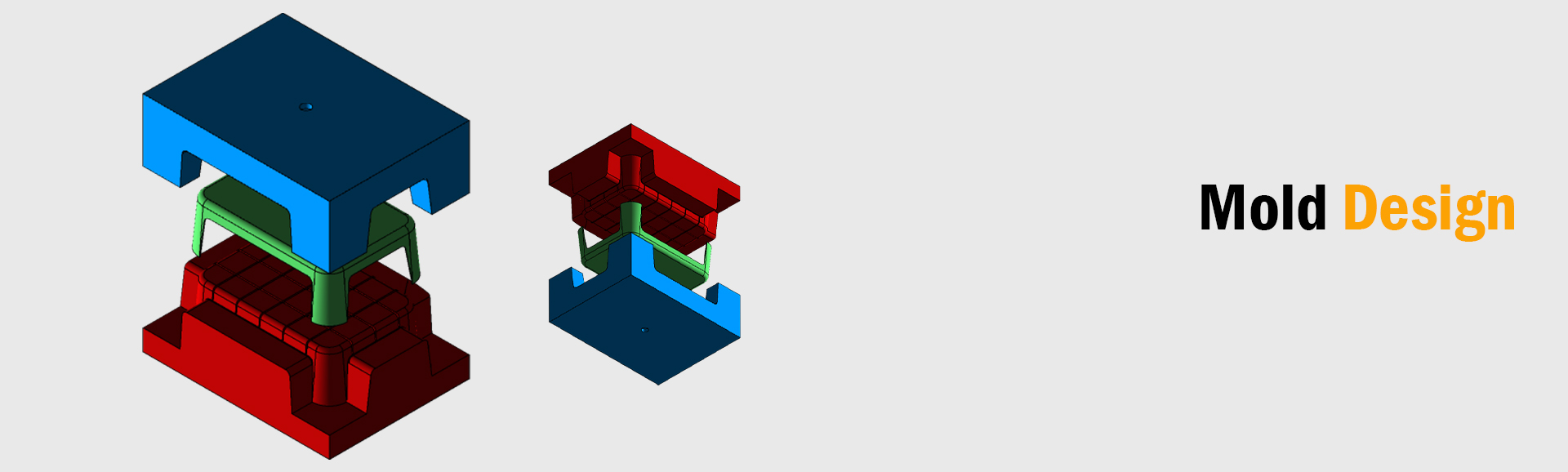

The innovative solutions for plastic die design in Clarksville Town, In have revolutionized manufacturing processes. These ultra modern approaches enhance efficiency, precision, and sustainability. Engineers in the region are employing state-of-the-art techniques to create molds that reduce material waste, optimize production timelines, and ensure premium quality output. By integrating advanced materials and technology, they are addressing environmental concerns associated with traditional plastic molding. The town's commitment to innovative plastic die design not only fosters local industry growth but also contributes to a greener and more sustainable future. This forward-thinking approach positions Clarksville Town as a hub for progressive solutions in the field of plastic manufacturing.

Evolution of Injection Molding Die Design in Clarksville Town, In

The evolution of injection molding die design in Clarksville Town, In has been remarkable. Over the years, advancements in technology and expertise have transformed the landscape of manufacturing. Engineers in the region have embraced innovative techniques to refine injection molding processes, resulting in increased efficiency and product quality. The integration of computer-aided design (CAD) and sophisticated materials has played a pivotal role in shaping these developments. As a result, for advanced injection die molding design, attracting attention for its commitment to staying at the forefront of industry advancements. This evolution not only enhances local manufacturing capabilities but also positions the town as a leader in injection molding innovation.

Challenges in plastic moulding die design in Clarksville Town, In

- Complex Geometries: Navigating intricate shapes and sizes while maintaining structural integrity poses a constant challenge in plastic moulding die design in Clarksville Town, IN.

- Material Selection: Precision in choosing the right materials is crucial to meet diverse production needs and ensure the durability of the molds.

- Adapting to Production Scales: The ability to adapt designs for both small-scale and large-scale production adds complexity to the process.

- Efficient Cooling Systems: Designing effective cooling systems is essential to prevent deformities and ensure consistent quality.

- Minimizing Production Time: Striking a balance between speed and precision is a continuous challenge in optimizing the production timeline.

- Innovation and Adaptability: To Stay ahead requires continual innovation and adaptability to meet the evolving demands of the dynamic manufacturing landscape in Clarksville Town.

Customization of mold and die design in Clarksville Town, In

The customization of mold and die design in Clarksville Town, In stands out as a key driver of manufacturing excellence. Local engineers are adept at tailoring designs to meet specific industry needs, fostering a culture of adaptability and innovation. Whether it's creating molds for intricate parts or specialized products, the emphasis on customization ensures precision and efficiency in production processes. The commitment to understanding unique client requirements, coupled with advancements in design technologies, has positioned it as a go-to destination for bespoke mold and die solutions. This dedication to customization not only supports local industries but also reinforces the town's reputation for flexible and client-centric manufacturing solutions.

Materials and Methods in Moulding Die Design in Clarksville Town, In

The selection of materials and methods in moulding die design in Clarksville Town, In plays a pivotal role in shaping efficient manufacturing processes. Local engineers employ a thoughtful approach, considering factors such as material durability, cost-effectiveness, and environmental impact. The use of advanced materials and innovative methods, including computer-aided design (CAD), ensures precision in crafting moulds. This attention to detail not only enhances the durability and quality of the moulds but also contributes to sustainable manufacturing practices. Their commitment to smart choices in materials and methods reflects a dedication to staying at the forefront of die moulding design, making it a hub for practical and forward-thinking solutions in the field.

When it comes to unmatched expertise in injection molding and die design, look no further than, 3D CAD Design Service. We pride ourselves on delivering unparalleled solutions tailored to your specific needs. Our experienced team excels in the intricate art of injection molding, ensuring precision and efficiency in every project. From ideation to the final product, we prioritize excellence, using cutting-edge 3D CAD technology to bring your ideas to life. Trust us to navigate the complexities of injection molding and die design, providing innovative and reliable solutions.